Abstract

Composite materials have played an important role throughout human history, from housing early civilizations to enabling future innovations. Composites offer many benefits; the key among them are corrosion resistance, design flexibility, durability, light weight, and strength. Composites have permeated our everyday lives such as products that are used in constructions, medical applications, oil and gas, transportation, sports, aerospace, and many more. Some applications, such as rocket ships, probably would not get off the ground without composite materials. This chapter addresses the advantages of fibre composite materials as well as fundamental effects, product development, and applications of fibre composites, including material chemistry, designing, manufacturing, properties, and utilisation of the materials in various applications.

Keywords

- fibre

- matrix

- composite

- fibre composite

- thermoset

- thermoplastic

- natural fibre

- biopolymer

Chapter and author info

Show +1. Introduction

Composites exist in nature. A piece of wood is a composite, with long cellulose fibres held together by a substance called lignin. Composite materials are formed by combining two or more materials that have quite different properties, and they do not dissolve or blend into each other. The different materials in the composite work together to give the composite unique properties. Humans have been using composite materials for thousands of years in different areas. The first uses of composites date back to the 1500 BC, when early Egyptians and Mesopotamian settlers used a mixture of mud and straw to create strong and durable buildings. The combination of mud and straw in a block of brick provides it a strong property against both squeezing and tearing or bending. The straw continued to provide reinforcement to ancient composite products, including pottery and boats [1]. In 1200 AD, the Mongols invented the first composite bow using a combination of “animal glue”, bone, and wood. The bows were pressed and wrapped with birch bark. These bows were powerful and accurate. Composite Mongolian bows helped to ensure Genghis Khan’s military dominance. Due to their advantages such as being light weight and strong, many of the greatest advancements in composites were the result of wartime needs. During World War II, many composite materials were developed and moved from the laboratory into actual production [1, 2].

The development and need for composite materials also result in the fibre-reinforced polymers (FRP) industry. By 1945, more than 7 million pounds of glass fibres were used for various products, primarily for military applications. Composite materials continued to take off after the war and grew rapidly through the 1950s. The composite innovators were ambitiously trying to introduce composites into other markets such as aerospace, construction, and transportation. Soon the benefits of FRP composites, especially its corrosion resistance, became known to the public sector. Boats were one obvious product that benefited. The first composite commercial boat hull was introduced in 1946. A full automobile body was made from composite and tested in 1947 [1, 2]. This led to the development of the 1953 Chevrolet Corvette. The advent of the automobile age gave rise to several new methods for moulding such as compression moulding of bulk moulding compound (BMC) and sheet moulding compound (SMC). The two techniques emerged as the dominant method of moulding for the automotive industry and other industries. In the early 1950s, manufacturing methods such as large-scale filament winding, pultrusion, and vacuum bag moulding were developed. In the 1960s, the marine market became the largest consumer of composite materials [1, 2]. In 1961, the first carbon fibre was patented and several years later became commercially available. In the 1970s the composites industry began to mature. Many better resins and improved reinforcing fibres were developed during this period for composite applications. In the 1970s, the automotive market surpassed marine as the number one market—a position it retains today. During the late 1970s and early 1980s, composites were first used in infrastructure applications in Asia and Europe. The first all-composites pedestrian bridge was installed in Aberfeldy, Scotland, in the 1990s. In this period, the first FRP-reinforced concrete bridge deck was built in McKinleyville, West Virginia, and the first all-composites vehicular bridge deck was built in Russell, Kansas. Composites continue to find applications today [1, 2, 3]. Nanomaterials are incorporated into improved fibres and resins used in new composites. Nanotechnology began to be used in commercial products in the early 2000s. Bulk carbon nanotubes can be used as composite reinforcement in polymers to improve the mechanical, thermal, and electrical properties of the bulk product [3].

Nowadays, the composite industry is still evolving, with much of the growth now focused around renewable energy. Wind turbine blades, especially, are constantly pushing the limits on size and require advanced composite materials, for example, the engineers can design to tailor the composite based on the performant requirements, making the composite sheet very strong in one direction by aligning the fibres that way, but weaker in another direction where strength is not so important. The engineers can also select properties such as resistance to heat, chemicals, and weathering by choosing an appropriate matrix material. In recent years, an increasing environmental consciousness and awareness of the need for sustainable development have raised interest in using natural fibres as reinforcements in composites to replace synthetic fibres [4, 5, 6, 7]. This chapter seeks to provide an overview of the science and technology in relation to the composite material, manufacturing process, and utilisation.

2. Polymer matrix

In general, a composite consists of three components: (i) the matrix as the continuous phase; (ii) the reinforcements as the discontinuous or dispersed phase, including fibre and particles; and (iii) the fine interphase region, also known as the interface [8, 9]. By carefully choosing the matrix, the reinforcement, and the manufacturing process that brings them together, the engineers can tailor the properties to meet specific requirements [10]. Over the recent decades, many new composites have been developed, some with very valuable properties.

Any material can serve as a matrix material for composite. However, matrix materials are generally ceramics, metals, and polymers. In reality, the majority of matrix materials that exist on the composites market are polymer. There are several different polymer matrices which can be utilised in composite materials. Among the polymer matrix composites, thermoset matrix composites are more predominant than thermoplastic composites. Though thermoset and thermoplastics sound similar, they have very different properties and applications. Understanding the performance differences can help to make better sourcing decisions and the product designs as composites [11].

Thermosets are materials that undergo a chemical reaction or curing and normally transform from a liquid to a solid. In its uncured form, the material has small, unlinked molecules known as monomers. The addition of a second material as a cross-linker, curing agent, catalyst, and/or the presence of heat or some other activating influences will initiate the chemical reaction or curing reaction. During this reaction, the molecules cross-link and form significantly longer molecular chains and cross-link network, causing the material to solidify. The change of the thermoset state is permanent and irreversible. Subsequently, exposure to high heat after solidifying will cause the material to degrade, not melt. This is because these materials typically degrade at a temperature below where it would be able to melt.

Thermoplastics are melt-process able plastics. The thermoplastic materials are processed with heat. When enough heat is added to bring the temperature of the plastic above its melting point, the plastic melts, liquefies, or softens enough to be processed. When the heat source is removed and the temperature of the plastic drops below its melting point, the plastic solidifies back into a glasslike solid. This process can be repeated, with the plastic melting and solidifying as the temperature climbs above and drops below the melting temperature, respectively. However, the material can be increasingly subject to deterioration in its molten state, so there is a practical limit to the number of times that this reprocessing can take place before the material properties begin to suffer. Many thermoplastic polymers are addition-type, capable of yielding very long molecular chain lengths or very high molecular weights [12].

Both thermoset and thermoplastic materials have its place in the market. In broad generalities, thermosets tend to have been around for a long time and have a well-established place in the market, frequently have lower raw material costs, and often provide easy wetting of reinforcing fibre and easy forming to final part geometries. In other words, thermosets are often easier to process than thermoplastic. Thermoplastics tend to be tougher or less brittle than thermoset. They can have better chemical resistance, do not need refrigeration as uncured thermosets (prepreg materials) frequently do, and can be more easily recycled and repaired. Table 1 presents a comparison between thermoset and thermoplastic. This table is not providing all but rather some information for the researchers and manufacturers when considering the utilisation of these materials.

| Thermoset | Thermoplastic | |

|---|---|---|

| Processing | Contain monomers that cross-link together during the curing process to form an irreversible chemical bond. The cross-linking process eliminates the risk of the product remelting when heat is applied, making thermosets ideal for high-heat applications such as electronics and appliances | Pellets soften when heated and become more fluid as additional heat is applied. This characteristic allows thermoplastics to be remoulded and recycled without negatively affecting the material’s physical properties |

| Features and benefits |

|

|

Table 1.

Thermoset vs. thermoplastic.

Thermosets are classified into polyester resins, epoxy resins, vinyl ester resins, phenolic, polyurethane, and other high-temperature resins such as cyanate esters, etc. The rapid industrialisation in developing economies the world over is one of the major boosting factors for the thermoset market. The demand for high-performance and lightweight materials from various end-use industries such as automotive, chemical tanks, and water tanks is expected to expand the global market for thermosets over the next 6 years. The growing demand for thermosets from emerging economies like Brazil, Russia, India, and China (BRIC) is expected to drive the market. BRIC nations are the four fastest-growing economies in the world with their GDP growth rates higher than the global GDP growth rate. However, frequent fluctuation in raw material prices acts as one of the major factors inhibiting the market growth. Asia-Pacific accounts for the biggest market for thermosets owing to the growth of the automobile market, primarily in China and India. Japan is a mature market and is expected to remain stagnant over the next years. China is the biggest automobile market in the world, and India also lists itself in the top five automobile markets in the world. Asia, along with being the largest market, is also the fastest-growing market for thermosets. The North American market for thermosets is primarily driven by the regulatory initiative to reduce automobile weight by 50% by 2020 in the USA in order to cut fuel consumption. Polyester resins and polyurethane account for the two most popular types of thermosets in the global market. The global market for thermosets is dominated by big multinational corporations which are present across the value chain. Some of the major companies operating in the thermosets market include Arkema, BASF, Asahi Kasei Chemical Corp, Bayer AG, Chevron Phillips Chemical Company LLC, Sinopec, Dow Chemical Company, Eastman Chemical Company, and Lyondell Basell Industries, among others [13]. To date, thermosets have been used predominantly in the industry. Thermosets are generally favoured for a variety of reasons, especially on commercial aircraft. Thermoset composites have been used for 30–40 years in aerospace. For example, the fuselage of the Boeing 787 is an epoxy-based polymer [14].

On the other hand, the use of thermoplastic polymers (acrylic, polyolefin, acrylonitrile butadiene styrene (ABS), etc.), the more easily moldable and resettable composite material relative to thermoset polymers, is a growing material trend in the fibre-reinforced polymer (FRP) industry. According to the American Composites Manufacturers Association (ACMA), the thermoplastic industry is expected to grow 4.9% over the next years and reach an estimated $8.2 billion by 2017, with even larger opportunities in emerging economies. Thermoplastic polymers also offer an easy solution to recycling composite components, a concern when it comes to adopting composite materials. Thermoplastic composites can repeat the heating and cooling cycle many times, thus giving the product an almost indefinite shelf life and adding more value for industries concerned with composite recyclability. This is especially the case for the growth of natural fibre thermoplastics in the USA and Western Europe. For example, wood-plastic composites, used for decking material and other wood substitutions, have grown by 35–40% in the past 5 years. According to Lucintel (the premier global management consulting and market research firm), countries in Asia and Eastern Europe will lead the growth for thermoplastic adoption because automotive production and thermoplastic automotive component production are quickly growing in those regions. However, the automotive sectors in the USA and Western Europe may not experience the same high rate of growth but are expected to develop steadily in the next 5 years, mainly due to the acceptance of new composite application. The study indicates that although gains will be limited by rising energy costs and competition from lower cost materials, there is significant opportunity in emerging economies such as China, Russia, Brazil, and India [15]. Recently, a major trend in the aerospace industry is a move toward greater use of thermoplastics vs. “traditional” thermoset epoxies. This also opens an opportunity for thermoplastics.

Thermoplastic are the dominant plastic materials overall, especially in non-reinforced applications. Thermosets are used in non-reinforced applications for a specific purpose where they have an advantage because of some unique property. However, within the reinforced or composites marketplace, thermoset dominant and thermoplastic are used only in applications where their unique advantages are important. Within the composite market, thermoset represents about 80% of the total material used [16]. The global composite resin market size by end-use applications, in terms of value, was USD 9317.4 Million in 2014 and is projected to grow at a CAGR of 5.6% between 2015 and 2020 [17].

As mentioned above, thermoplastics are capable of being repeatedly softened by the application of heat and hardened by cooling and have the potential to be the most easily recycled, which has seen them most favoured in recent commercial uptake, whereas better realisation of the fibre properties is generally achieved using thermosets. There are several types of polymers in the market. The most common polymers are summarized in Table 2 [18, 19, 20, 21, 22, 23].

| Polymers | Density (g/cm3) | Elongation (%) | Tensile strength (MPa) | Young’s modulus (GPa) | |

|---|---|---|---|---|---|

| Thermoplastic | Acrylonitrile styrene acrylate (ASA) | 1.0–1.1 | 30.0 | 43.5 | 2.2 |

| Acrylonitrile butadiene styrene (ABS) | 1.0–1.1 | 270.0 | 47.0 | 2.1 | |

| Cross-linked polyethylene (PE) | 0.9 | 350.0 | 18.0 | 0.5 | |

| Ethylene vinyl acetate (EVA) | 0.9–1.0 | 750.0 | 17.0 | 0.02 | |

| High-density polyethylene (HDPE) | 0.9–1.0 | 150.0 | 32.0–38.2 | 1.3 | |

| High-impact polystyrene (HIPS) | 1.0 | 2.5 | 42.0 | 2.1 | |

| Low-density polyethylene (LDPE) | 0.9 | 400.0 | 10.0–11.6 | 0.2–0.3 | |

| Nylon 6 (PA 6) | 1.1 | 60.0 | 81.4 | 2.8 | |

| Nylon 66 (PA 66) | 1.1 | 60.0 | 82.7 | 2.8 | |

| Perfluoroalkoxy (vinyl ether) | 2.15 | 260.0–300.0 | 28.0–31.0 | 0.50–0.60 | |

| Polybutylene (PB) | 0.95 | 220–300 | 29.0–35.0 | 0.29–0.30 | |

| Polylactic acid (PLA) | 1.2–1.3 | 2.1–30.7 | 5.9–72.0 | 1.1–3.6 | |

| Polycarbonate (PC) | 1.2 | 200.0 | 69.0 | 2.3 | |

| Polycaprolactone (PCL) | 1.1 | 700.0 | 16.0–23.0 | 0.4 | |

| Polyethylene cross-linked (PEX) | 0.92 | 20.0 | |||

| Polyethylene terephthalate (PET) | 1.5–1.6 | 300.0 | 55.0–159.0 | 2.3–9.0 | |

| Polyether ether ketone (PEEK) | 1.3–1.5 | 1.6–50.0 | 92.0–95.0 | 3.7–24.0 | |

| Polyether ketone (PEK) | 1.2–1.4 | 20.0 | 100.0–110.0 | 3.5 | |

| Polyhydroxyalkanoates (PHA) | 1.2–1.3 | 2.0–1200.0 | 10.0–39.0 | 0.3–3.8 | |

| Polyhydroxybutyrate (PHB) | 1.2 | 1.56–6.0 | 24.0–40.0 | 3.5–7.7 | |

| Poly-3-hydroxybutyrate (P-3-HB) | 1.3 | 0.4–6.0 | 40.0 | 3.5 | |

| Poly-3-hydroxybutyrate-co-3-hydroxyvalerate (P-3-HB-3 HV) | 0.2–0.3 | 1.6–20.0 | 23.0–40.0 | 3.5 | |

| Poly-3-hydroxybutyrate (P-3-HB) | 1.2 | 1000.0 | 104.0 | — | |

| Poly(methyl methacrylate) (PMMA) | 1.1–1.2 | 2.5 | 72.4 | 3.0 | |

| Polypropylene (PP) | 0.9–1.3 | 80.0 | 35.8 | 1.6 | |

| Polystyrene (PS) | 1.04 | 1.6 | 34.0 | 3.0 | |

| Polytetrafluoroethylene (PTFE) | 2.20 | 40.0–650.0 | 0.862–41.4 | 0.392–2.25 | |

| Polyvinyl chloride (PVC) | 1.3–1.5 | 50.0–80.0 | 52.0–90.0 | 3.0–4.0 | |

| Polyvinylidene fluoride (PVDF) | 1.8 | 50.0 | 43.0 | 2.0 | |

| Rigid thermoplastic Polyurethane (RTPU, PUR-RT) | 1.1 | 5.0 | 75.0 | 4.0 | |

| Thermoset | Epoxy (EP) | 1.2–1.3 | 1.3 | 55.0–130.0 | 2.7–4.1 |

| Melamine formaldehyde (MF) | 1.5–1.6 | 0.6 | 65.0 | 12.0 | |

| Phenol formaldehyde (PF) | 1.2 | 1.2 | 45.0–60.0 | 4.0–7.0 | |

| Rigid thermoset polyurethane (RPU) | 1.2 | 90.0 | 60.0 | 2.2 | |

| Unsaturated polyester (UPE) | 1.1 | 2.0 | 34.0–105.0 | 2.1–3.5 | |

| Urea formaldehyde (UF) | 1.5–1.6 | 0.8 | 65.0 | 9.0 | |

| Polyurethane rubber | 1.2–1.3 | 300.0–580.0 | 39.0 | 2.0–10.0 | |

| Vinyl ester (VE) | 1.23 | 2.0–12.0 | 73.0–81.0 | 3.0–3.5 |

Table 2.

Properties of some polymers.

3. Reinforcements

Composite reinforcements can be in various forms such as fibres, flakes, or particles. Each of these has its own properties which can be contributed to the composites, and therefore, each has its own area of applications. Among the forms, fibres are the most commonly used in composite applications, and they have the most influence on the properties of the composite materials. These reasons are that the fibres have the high aspect ratio between length and diameter, which can provide effective shear stress transfer between the matrix and the fibres, and the ability to process and manufacture the composites part in various shapes using different techniques.

Various types of fibres have been utilised to reinforce polymer matrix composites. The most common are carbon fibres (AS4, IM7, etc.), glass fibre (E-glass, S-glass, etc.), aramid fibres (Kevlar® and Twaron®), and boron fibres. Glass fibres have been used as reinforcement for centuries, notably by Renaissance Venetian glass workers. Commercially important continuous-glass fibre filaments were manufactured in 1937 by a joint venture between Owens-Illinois and Corning Glass. A variety of glass fibre compositions are available for different purposes as presented below. Table 3 shows compositions of some commonly used glass fibres for composite materials.

Grade A is high alkali grade glass, originally made from window glass.

Grade C is chemical-resistant grade glass for acid environments or corrosion.

Grade D is low dielectric grade glass, good transparency to radar (quartz glass).

Grade E is electrical insulation grade; this is the most common reinforcement grade.

Grade M is high modulus grade glass.

Grade R is reinforcement grade glass; this is the European equivalent of S-glass.

Grade S is high strength grade glass, a common variant is S2-glass. This fibre has higher Young’s modulus and temperature resistance than E-glass. It is also significantly more expensive.

| Oxide | E-glass with boron | E-glass without boron | ECR-glass | S-2 glass | R-glass | Effect on fibre properties |

|---|---|---|---|---|---|---|

| SiO2 | 52–56 | 59 | 54–62 | 64–66 | 60–65 | Very low thermal expansion |

| Al2O3 | 12–16 | 12.1–13.2 | 9–15 | 24–26 | 17–24 | Improved chemical durability |

| B2O3 | 5–10 | — | — | — | — | Low thermal expansion |

| CaO | 16–25 | 22–23 | 17–25 | — | 5–11 | Resistance to water, acids, and alkalis |

| MgO | 0–5 | 3.1–3.4 | 0–5 | 8–12 | 6–12 | Resistance to water, acids, and alkalis |

| ZnO | — | — | 2.9 | — | — | Chemical durability |

| Na2O | 0–1 | 0.6–0.9 | 1.0 | 0–0.1 | 0–2 | High thermal expansion, moisture sensitivity |

| K2O | Trace | 0–0.2 | 0.2 | — | 0–2 | High thermal expansion, moisture sensitivity |

| TiO2 | 0.2–0.5 | 0.5–1.5 | 2.5 | — | — | Improved chemical durability especially alkali resistance |

| Zr2O3 | — | — | — | 0–1 | — | — |

| Li2O | — | — | — | — | — | High thermal expansion, moisture sensitivity |

| Fe2O3 | 0.2–0.4 | 0.2 | 0.1 | 0–0.1 | — | Green colouration |

| F2 | 0.2–0.7 | 0–0.1 | Trace | — | — | — |

Table 4 presents the mechanical properties of the main grades of glass fibre for composite materials.

| Fibre | Density (kg/m3) | Young’s modulus (GPa) | Virgin filament strength (MPa) | Roving strength (MPa) | Strain to failure (%) |

|---|---|---|---|---|---|

| A (alkali) | 2460 | 73 | 3100 | 2760 | 3.6 |

| C (chemical) | 2460 | 74 | 3100 | 2350 | ∼ |

| D (dielectric) | 2140 | 55 | 2500 | ∼ | ∼ |

| E (electrical) | 2550 | 71 | 3400 | 2400 | 3.37 |

| R (reinforcement) | 2550 | 86 | 4400 | 3100 | 5.2 |

| S (strength) | 2500 | 85 | 4580 | 3910 | 4.6 |

| S2 | 2460 | 90 | 3623 | ∼ | ∼ |

| S3 | 2830 | 99 | 3283 | ∼ | ∼ |

Table 4.

Mechanical properties of the main grades of glass fibre [24].

Carbon fibre was first invented near Cleveland, Ohio, in 1958. It wasn’t until a new manufacturing process was developed at a British research centre in 1963 that carbon fibre’s strength potential was realised [27]. The principle precursors for carbon fibres are polyacrylonitrile (PAN), pitch, cellulose (Rayon), and some other potential precursors such as lignin and polyethylene. Carbon fibres are manufactured by stretching PAN polymer precursor, melt spinning of molten pitch, and graphitization under tensile stress [28].

The modulus of carbon fibres depends on the degree of perfection of the alignment. Imperfections in alignment results in complex shaped voids elongated parallel to the fibre axis, which act as stress raisers and points of weakness. The alignment varies considerably with the manufacturing route and conditions. High-modulus fibres are those which have been subjected to heat treatment in excess of 1650°C, possess three-dimensional ordering of the atoms, have carbon contents above 99% (although their graphitic structure is still less than 75%), and have a tensile modulus above 350 GPa. High-modulus, high-strength carbon fibres have diameters of 7–8 μm and consist of small crystallites of “turbostratic” graphite. The layers have no regular stacking sequence, and the average spacing between the planes is 0.34 nm. To obtain high modulus and strength, the layer planes of the graphite must be aligned parallel to the fibre axis [29]. Carbon fibres have several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, and high temperature. The carbon fibres can be utilised in various applications such as aerospace, automotive, sporting goods, and consumer goods. Table 5 shows properties for the different grades of carbon fibre.

| Precursor | PAN | PAN | Pitch | Pitch | Rayon | Pitch (K13D2U) |

|---|---|---|---|---|---|---|

| Modulus | Low | High | Low | High | Low | Ultrahigh |

| Tensile modulus (GPa) | 231 | 392 | 161 | 385 | 41 | 931 |

| Tensile strength (GPa) | 3.4 | 2.5 | 1.4 | 1.8 | 1.1 | 3.7 |

| Strain to failure (%) | 1.4 | 0.6 | 0.9 | 0.4 | 2.5 | 0.4 |

| Relative density | 1.8 | 1.9 | 1.9 | 2.0 | 1.6 | 2.2 |

| Carbon assay (%) | 94 | 100 | 97 | 99 | 99 | >99 |

Table 5.

Indicative properties for the different grades of carbon fibre [27].

Kwolek is a DuPont chemist who in 1965 invented an aramid fibre known as Kevlar, the lightweight, stronger-than-steel fibre used in bulletproof vests and other body armour around the world. The chemical structure of the materials is being alternated aromatic (aryl) benzene rings and the amide (CONH) group. The commercial name of the reinforcement’s fibres is Kevlar from DuPont and Twaron from AkzoNobel, which are believed to be poly-(para-phenylene terephthalamide). The polymer is produced by the elimination of hydrogen chloride from terephthaloyl chloride and para-phenylene diamine. The polymer is washed and dissolved in sulphuric acid to form a partially oriented liquid crystal solution. The solution is spun through small die holes, orientation taking place in the spinnerette, and the solvent is evaporated. Hull suggests that the solution is maintained between −80°C and −50°C before spinning and is extruded into a hot-walled cylinder at 200°C. Kevlar was introduced for commercial products in 1971. There are three principal types of Kevlar fibre as shown in Table 6.

| Fibre type | E (GPa) | σ’ (GPa) | ε’ (%) | |

|---|---|---|---|---|

| Kevlar 29 | High-toughness, high-strength, intermediate modulus for tyre cord reinforcements | 83 | 3.6 | 4.0 |

| Kevlar 49 | High modulus high-strength for composite reinforcement | 131 | 3.6 | 2.8 |

| Kevlar 149 | Ultra-high modulus recently introduced | 186 | 3.4 | 2.0 |

Table 6.

Characteristics of the different grades of aramid fibre [27].

Recently, with advantages of reasonable mechanical properties, low density, environmental benefits, renewability, and economic feasibility, natural fibres have been paid more attention to in composite applications. The natural fibres in simple definition are fibres that are not synthetic or man-made and are categorized based on their origin from animals, mineral, or plant sources [30]. Natural fibres are one such proficient material which would be utilised to replace the synthetic materials and their related products for the applications requiring less weight and energy conservation. Natural plant fibres are entirely derived from vegetative sources and are fully biodegradable in nature. Fibre-reinforced polymer matrix got considerable attention in numerous applications because of its good properties. The current indicators are that interest in natural fibre composites by the industry will keep growing quickly around the world. The application of natural fibre-reinforced polymer composites and natural-based resins for replacing existing synthetic polymer or glass fibre-reinforced materials is huge. However, natural fibre quality is influenced significantly by the age of the plant, species, growing environment, harvesting, humidity, quality of soil, temperature, and processing steps, and there is a move to reduce the on-field processing to improve consistency and reduce costs. The properties of several natural fibres and commonly used synthetic fibres are shown in Table 7 [31, 32, 33, 34, 35].

| Fibre | Density (g/cm3) | Elongation (%) | Tensile strength (MPa) | Young’s modulus (GPa) |

|---|---|---|---|---|

| Abaca | 1.5 | — | 511.0–1051.0 | 13.5–29.8 |

| Alfa | 0.89 | — | 350.0 | 22.0 |

| Bagasse | 1.2 | 1.1 | 20.0–290.0 | 19.7–27.1 |

| Banana | 1.3–1.4 | 2.0–7.0 | 54.0–789.0 | 3.4–32.0 |

| Bamboo | 1.5 | — | 575.0 | 27.0 |

| Coconut | 1.4–3.8 | — | 120.0–200.0 | 19.0–26.0 |

| Coir | 1.2 | 15.0–30.0 | 175.0–220.0 | 4.0–6.0 |

| Cotton | 1.5–1.6 | 3.0–10.0 | 287.0–597.0 | 5.5–12.6 |

| Curaua | 1.4 | — | 825.0 | 9.0 |

| Flax | 1.4–1.5 | 1.2–3.2 | 345.0–1500.0 | 27.6–80.0 |

| Hemp | 1.4–1.5 | 1.6 | 550.0–900.0 | 70.0 |

| Henequen | 1.4 | 3.0–4.7 | 430.0–580.0 | — |

| Isora | 1.2 | — | 550.0 | — |

| Jute | 1.3–1.5 | 1.5–1.8 | 393.0–800.0 | 10.0–30.0 |

| Kapok | 0.4 | — | 93.3 | 41.0 |

| Kenaf | 1.2 | 2.7–6.9 | 295.0 | — |

| Palf | 1.4 | 3.0 | 170.0–635.0 | 6.2–24.6 |

| Piassava | 1.4 | — | 138.5 | 2.8 |

| Pineapple | 1.5 | 1.0–3.0 | 170.0–1672.0 | 82.0 |

| Ramie | 1.5 | 2.0–3.8 | 220.0–938.0 | 44.0–128.0 |

| Silk | 1.3–1.4 | — | 650.0–750.0 | 16.0 |

| Sisal | 1.3–1.5 | 2.0–14.0 | 400.0–700.0 | 9.0–38.0 |

| Softwood Kraft | 1.5 | — | 1000.0 | 40.0 |

| Wool | 120.0–174.0 | 5.0–10.9 |

Table 7.

Properties of several natural fibres and commonly used synthetic fibres.

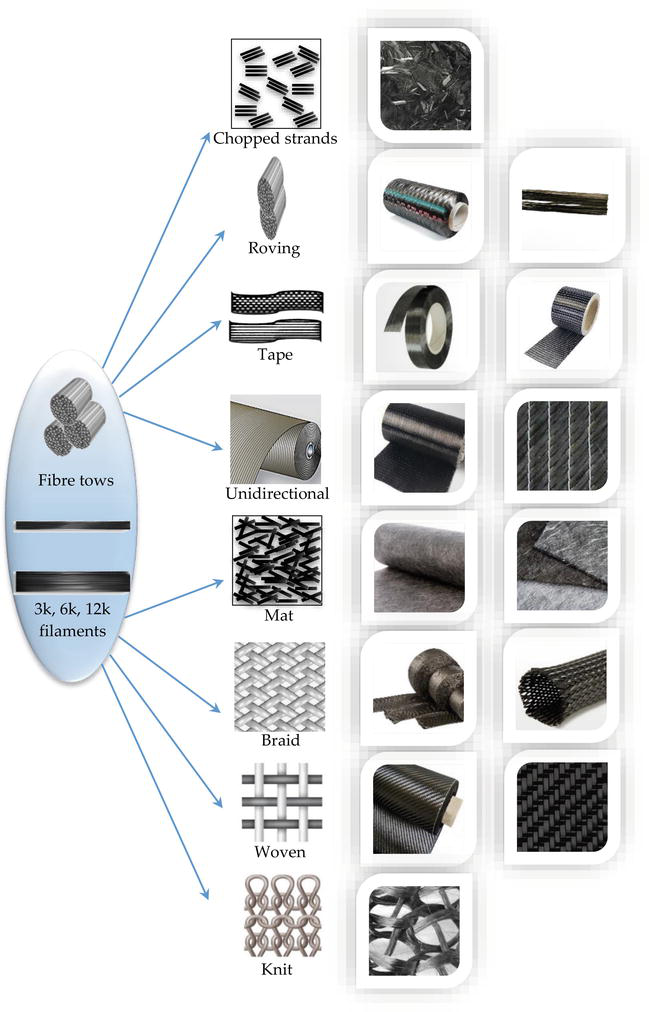

Increasingly, the fibres have replaced parts formerly made of steel. The fibres used in composite materials appear at different forms and scales as shown in Figure 1.

Figure 1.

Various fibre forms.

4. Composite manufacturing techniques

There are several methods for fabricating composite materials. The selection of a method for a part will depend on the materials, the part design, the performance, and the end-use or application.

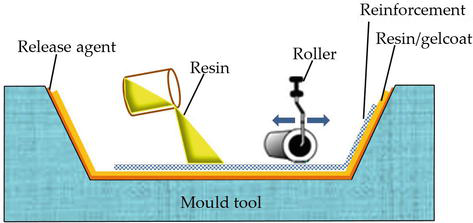

4.1 Open contact moulding

Hand lay-up is an open contact moulding technique for fabricating composite materials. Resins are impregnated by the hand into fibres which are in the form of woven, knitted, stitched, or bonded fabrics. In this technique, the mould is first treated with mould release, dry fibres or dry fabrics are laid on a mould, and liquid resin is then poured and spread onto the fibre beds [36]. This is usually accomplished by rollers or brushes, with an increasing use of nip-roller-type impregnators for forcing resin into the fabrics by means of rotating rollers and a bath of resin. A roller or brush is used to wet the fibres and remove air trapped into the lay-ups. A few layers of fibres are wetted, and laminates are left to cure under standard atmospheric conditions. After these layers are cured, more layers are added, as shown in Figure 2.

Figure 2.

Hand lay-up process.

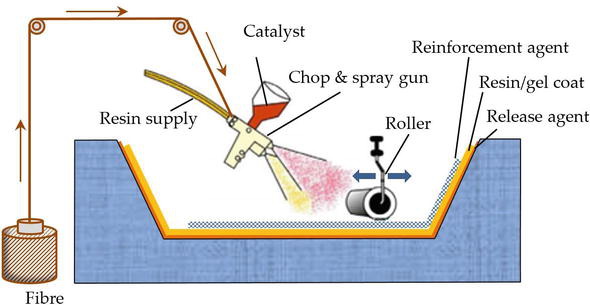

Spray-up is also an open-mould application technique for composite. The spray lay-up technique is considered an extension of the hand lay-up method. In this process, the mould is first treated with mould release. If a gel coat is used, it is sprayed into the mould at a certain thickness after the mould release has been applied. The gel coat then is cured, and the mould is ready for process. The fibre and catalysed resin at a viscosity of 500–1000 cps are sprayed into the mould using a chopper spray gun. The gun chops continuous fibre tow into short-fibre bundle lengths and then blows the short fibres directly into the sprayed resin stream so that both materials are applied simultaneously on the surface of the mould, as shown in Figure 3. In the final steps of the spray-up process, the workers compact the laminate by hand with rollers. The composite part is then cured, cooled, and removed from the mould [37, 38].

Figure 3.

The schematic of the spray lay-up process.

Hand lay-up and spray-up methods are often used in tandem to reduce labour cost. This is a common process for making glass fibre composite products such as bathtubs, boat hulls and decks, fenders, RV components, shower stalls, spas, truck cabs, and other relatively large and noncomplex shapes.

4.2 Resin infusion processes

With the ever-increasing demand for faster production rates, the industry has used alternative fabrication processes to replace hand lay-up as well as encouraged fabricators to automate those processes wherever possible.

Resin transfer moulding (RTM), sometimes referred to as liquid moulding, is a fairly simple process. In this technique, the mould is first treated with mould release. The dry reinforcement, typically a preform, is then placed into the mould and the mould is closed. Low viscosity resin and catalyst are metered and mixed and then pumped into the mould under low-to-moderate pressure through injection ports, following predesigned paths through the preform. Low-viscosity resin is used in RTM technique to ensure that the resin permeates through the preform quickly and thoroughly before gel and cure, especially with thick composite parts.

Reaction injection moulding (RIM) injects a rapid cure resin and a catalyst into the mould in two separate streams. Mixing and chemical reaction occur in the mould instead of in a dispensing head. Automotive industry suppliers have combined structural RIM (SRIM) with rapid preforming methods to fabricate structural parts that do not require a class A finish. Figure 4 describes the schematic of the RTM process [39, 40].

Figure 4.

The schematic of the RTM process.

Representing the fastest-growing moulding technology is vacuum-assisted resin transfer moulding (VARTM), as shown in Figure 5. The difference between VARTM and RTM is that in VARTM, resin is drawn into a preform use a vacuum only, rather than pumped in under pressure as RTM. VARTM technique does not require high heat or pressure. VARTM usually operates with low-cost tooling, making it possible to inexpensively produce large, complex parts in one shot [41, 42, 43].

Figure 5.

The schematic of the VARTM process.

Resin film infusion (RFI) is a hybrid process in which a dry preform is placed in a mould on top of a layer, or interleaved with multiple layers, of high-viscosity resin film. Under applied heat, vacuum, and pressure, the resin liquefies and is drawn into the preform, resulting in uniform resin distribution, even with high-viscosity, toughened resins, because of the short flow distance. Using the resin infusion techniques, the fibre volumes can be up to 70%, and automated controls ensure low voids and consistent preform reproduction, without the need for trimming. Resin infusion has found significant application in boatbuilding. This method has been employed by The Boeing Co. (Chicago, IL, USA) and NASA, as well as small fabricating firms, to produce aerospace-quality laminates without an autoclave [36, 44]. Figure 6 presents the schematic of the resin film infusion process.

Figure 6.

The schematic of the resin film infusion process.

4.3 Compression moulding

Compression moulding is a precise and potentially rapid process for producing high-quality composite parts in a wide range of volumes. The material is manually or robotically placed in the mould. The mould halves are closed, and pressure is applied using hydraulic presses. Cycle time ranges depending on the part size and thickness. This process produces high-strength, complex parts in a wide variety of sizes. The composites are commonly processed by compression moulding and include thermosetting prepregs, fibre-reinforced thermoplastic, moulding compounds such as sheet moulding compound (SMC), bulk moulding compounds (BMC), and chopped thermoplastic tapes. Figure 7 shows the schematic of the compression moulding process.

Figure 7.

The schematic of compression moulding process.

4.4 Injection moulding

Injection moulding is a closed process as shown in Figure 8. This is fast, high-volume, low-pressure, and most commonly used for filled thermoplastics, such as nylon with chopped glass fibre. The injection-moulding process has been in use for nearly 150 years. Reciprocating screw injection-moulding machines were introduced in the 1960s and are still used today [45]. Injection speeds are typically one to a few seconds, and many parts can be produced per hour in some multiple cavity moulds.

Figure 8.

Simplified diagram of moulding process.

4.5 Filament winding

Filament winding is a continuous fabrication method that can be highly automated and repeatable, with relatively low material costs as shown in Figure 9. A long, cylindrical tool called a mandrel is suspended horizontally between end supports. Dry fibres are run through a bath of resin to be wetted. The fibre application instrument moves back and forth along the length of a rotating mandrel with the traverse carriage, placing fibre onto the tool in a predetermined configuration. Computer-controlled filament-winding machines are used to arrange the axes of motion [46, 47, 48]. Filament winding is one example of aerospace composite materials.

Figure 9.

The schematic of the filament winding process.

4.6 Pultrusion process

Composite pultrusion is a processing method for producing continuous lengths of fibre-reinforced polymer structural shapes with constant cross-sections. This is a continuous fabrication method that can be highly automated. In this process, a continuous bundle of dry fibre is pulled through a heated resin-wetting station. The wetted bundle is pulled into heated dies, and the cross-sectional shape of the pulled fibre is formed by these dies. The resin is cured, and the composites are formed. Parts are then made by slicing the long-cured piece. This process is limited to straight parts with a constant cross-section, such as I-beams, T-beams, or frame sections and ladder rails. Figure 10 shows the schematic of the pultrusion process [49, 50]. Pultrusion is used in the manufacture of linear components such as ladders and mouldings.

Figure 10.

The schematic of the pultrusion process.

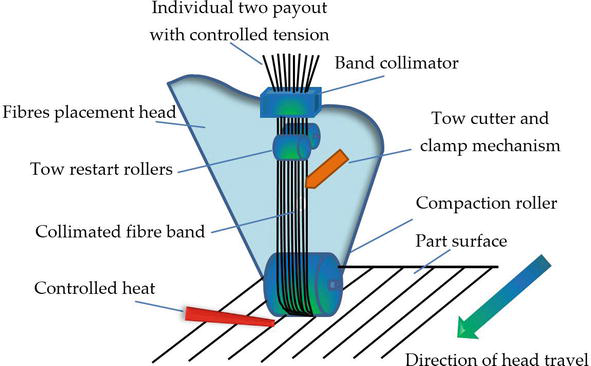

4.7 Automated fibre placement

Automated fibre placement (AFP) is one of the most advanced methods for fabricating and manufacturing of composite materials as presented in Figure 11. This method is used almost exclusively with continuous fibre-reinforced tape. A robot is utilised to place fibre-reinforced tape and build a structure one ply (layer) at a time. A band of material comprised of multiple narrow strips of tape (tows) is placed where these tows are commonly 0.125 and 0.25 inches wide. The use of robotics gives the operator active control over all the processes critical variables, making the process highly controllable and repeatable. This method allows the fabrication of highly customised parts as each ply can be placed at different angles to best carry the required loads [51, 52].

Figure 11.

The schematic of the automated fibre placement process.

Advantages of fibre placement are processing speed and reduced material scrap and labour costs. Often, the process is utilised to fabricate large thermoset parts with complex shapes. Similar to ATP process, automated tape laying (ATL) is an even speedier automated process in which prepreg tape, rather than single tows, is laid down continuously to form parts.

4.8 Additive manufacturing

Additive manufacturing is also known as 3D printing technique. Additive manufacturing is a step change in the development of rapid prototyping concepts that were introduced more than 20 years ago. This is a process for making a solid object from a three-dimensional digital model, typically by laying down many successive thin layers of a material. Manufacturing a composite structure with a single nozzle uses polymer composite filament and contains polymer and additives such as rubber microspheres, particles of glass or carbon fibre, wood flour, etc. as shown in Figure 12. This more recent form of composite part production grew out of efforts to reduce the costs in the design-to-prototype phase of product development, taking aim particularly at the material-, labour-, and time-intensive area of toolmaking [53, 54, 55, 56].

Figure 12.

The schematic of the 3D printing process for polymer composites.

4.9 Composite properties

The polymer composite materials are lightweight, which increases the fuel efficiency of vehicles manufactured from composites and gives them structural stability. In addition, they offer a high strength-to-weight ratio and increased heat resistance. Composites have very different properties and applications depending on the type of matrix, reinforcement, ratio between them, formulations, processing etc. The bonding strength between fibre and polymer matrix in the composite is considered one of the major factors in order to obtain superior fibre reinforcement polymer composite properties. Typical properties of several polymer composites are presented in Table 8 [57, 58, 59, 60, 61, 62, 63, 64, 65, 66, 67, 68, 69, 70, 71].

| Composite | Density (g/cm3) | Elongation (%) | Tensile strength (MPa) | Young’s modulus (GPa) |

|---|---|---|---|---|

| ABS + 30% glass fibre | — | 2.0 | 60.0 | 9.0 |

| Acetal copolymer + 30% glass fibre | — | 3.0 | 110.0 | 9.5 |

| Epoxy + 40–60% carbon fibre | 1.15–2.25 | 0.4–11.0 | 4.6–3220.0 | 2.6–520.0 |

| Epoxy + 45% flax yarn-aligned | — | — | 133.0 | 28.0 |

| Epoxy + 40% glass fibre | — | — | — | — |

| Epoxy + 52% jute fibre | — | — | 216.0 | 31.0 |

| Epoxy + 52% kevlar fibre | — | — | 434.0 | 28.2 |

| PEEK + 62% carbon fibre | 1.60 | — | 750.0 | 50.0 |

| PEEK + kevlar fibre | 1.31–1.50 | 1.0–6.0 | 75.0–193.0 | 4.0–20.7 |

| Nylon 66 + 25–30% carbon fibre | 1.20–1.57 | 0.90–4.0 | 193.0–261.0 | 16.0–33.1 |

| Nylon 6 + 40% glass fibre | 1.45 | 2.0–3.0 | 235.0 | 12.9 |

| Nylon + kevlar fibre | 1.16 | 4.0 | 110.0 | 9.0 |

| PLA + 30% abaca fibre | — | — | 74.0 | 8.0 |

| PLA + 20% bamboo fibre | — | — | 90.0 | 1.8 |

| PLA + 30% flax fibre | — | — | 53.0–100.0 | 8.0 |

| PF + E glass fibre | 1.5–1.65 | — | 85.0–330.0 | 5.0–17.0 |

| Polycarbonate + 5–40% carbon fibre | 1.15–1.43 | 0.9–118.0 | 46.0–186.0 | 2.1–25.5 |

| Polycarbonate + 30–40% glass fibre | 1.44–1.52 | 4.0 | 107.0–159.0 | 10.0–11.6 |

| Polycarbonate-ABS + 30% glass fibre | 1.29 | — | 82.7 | — |

| Polyimide + 20–30% carbon fibre | 1.38–1.68 | 0.8–5.5 | 36.5–241.0 | 4.5–29.0 |

| Polyimide + glass fibre | — | 2.0 | 150.0 | 12.0 |

| PP + 30% carbon fibre | 1.07 | 1.0 | 117.0 | 16.2 |

| PP + 30% cotton fibre | — | — | 58.5 | 4.1 |

| PP + 20% glass-chopped strand mat | — | — | 77.0 | 5.4 |

| PP + 20% glass fibre | 1.03 | 3.0–4.0 | 100.0 | 4.3 |

| PP + 40% glass fibre | 1.22 | 2.0 | 127.0 | 7.6 |

| PP-MAgPP + 40% hemp fibre | — | — | 52.0 | 4.0 |

| UPE + 35% jute fibre | — | — | 50.0 | 8.0 |

| UPE + 47% glass fibre | — | — | 201.0 | 13.0 |

| Vinylester + carbon fibre | 1.50–1.65 | 1.4 | 900.0–1200.0 | 136.0 |

| Vinylester + 24% flax fibre | — | — | 248.0 | 24.0 |

| Vinylester + 59% glass fibre | — | — | 483.0 | 33.0 |

| Vinylester + kevlar fibre | 1.35 | — | 500.0 | 40.0 |

Table 8.

Properties of several fibre-reinforced polymer composites.

The growth of the composites market can be attributed to increased uses in the aerospace, defence, and transportation applications. The global composite materials market is expected to reach an estimated $40.2 billion by 2024, and it is forecasted to grow at a CAGR of 3.3% from 2019 to 2024. The global composite product market is expected to reach an estimated $114.7 billion by 2024 [72].

5. Composite applications

The most widely used form of fibre-reinforced polymer is a laminar structure, made by stacking and bonding thin layers of fibre and polymer until the desired thickness is obtained. By changing the fibre orientation among layers in the laminate structures, a specified level of anisotropy in composite properties can be achieved. Composites offer many benefits such as corrosion resistance, light weight, strength, lower material costs, improved productivity, design flexibility, and durability. Therefore, the wide range of industries uses composite materials and some of their common applications [3, 15].

5.1 Aerospace

The major original equipment manufacturers (OEMs) such as Airbus and Boeing have shown the potential of using composite materials for large-scale applications in aviation. NASA is continually looking to composite manufacturers for innovative approaches and space solutions for rockets and other spacecrafts. Composites with thermoset are being specified for bulkheads, fuselages, wings, and other applications in commercial, civilian, and military aerospace applications. There are several other applications of composites in the areas such as air-foil surfaces, antenna structures, compressor blades, engine bay doors, fan blades, flywheels, helicopter transmission structures, jet engines, radar, rocket engines, solar reflectors, satellite structures, turbine blades, turbine shafts, rotor shafts in helicopters, wing box structures, etc. [3, 15, 26, 37]

5.2 Appliance/business

Composite materials offer flexibility in design and processing; therefore composite materials can be used as alternatives for metal alloys in appliances. Unlike most other industries, trends within the appliance segment move quite quickly. In addition, design and function are subject to both technology advancements and changing consumer taste. Composite materials are being used in appliance and business equipment such as equipment panels, frames, handles and trims in appliances, power tools, and many other applications. Composites are being utilised for the appliance industry in dishwashers, dryers, freezers, ovens, ranges, refrigerators, and washers. The components in the equipment that were utilised composites include consoles, control panels, handles, kick plates, knobs, motor housings, shelf brackets, side trims, vent trims, and many others [3, 73].

5.3 Architecture

With their aesthetic qualities, functionality, and versatility, the composite materials are becoming the material of choice for architectural applications. Composite materials allow architects to create designs that are impractical or impossible with traditional materials, improve thermal performance and energy efficiency of building materials, and meet building code requirements. Composite materials also offer design flexibility and can be moulded into complex shapes. They can be corrugated, curved, ribbed, or contoured in a variety of ways with varying thickness. Further, a traditional look such as copper, chrome or gold, marble, and stone can be achieved at a fraction of the cost using composite materials. Therefore, the architecture community is experiencing substantial growth in the understanding and use of composites in commercial and residential buildings [15].

5.4 Automotive and transportation

The automotive industry is no stranger to composites. This is one of the largest markets for composite materials. Weight reduction is the greatest advantage of composite material usage. A lower-weight vehicle or truck is more fuel-efficient because it requires less fuel to propel itself forward. In addition to enabling ground breaking vehicle designs, composites help make vehicles lighter and more fuel efficient. The composite materials are used in bearing materials, bodies, connecting rod, crankshafts, cylinder, engines, piston, etc. While fibre-reinforced polymers such as CFRP in cars get most of the attention, composites also play a big role in increasing fuel efficiency in trucks and transport systems. A number of US state Departments of Transportation are also using composite to reinforce the bridges those trucks travel on [3, 26, 37].

5.5 Construction and infrastructure

Construction is one of the largest markets for composites globally. The composites can be made to have a very high strength and ideal construction materials. Thermoset composites are replacing many traditional materials for home and offices’ architectural components including doors, fixtures, moulding, roofing, shower stalls, swimming pools, vanity sinks, wall panels, and window frames. Composites are used all over the world to help construct and repair a wide variety of infrastructure applications, from buildings and bridges to roads, railways, and pilings [3, 74].

5.6 Corrosive environments

Products made from composite materials provide long-term resistance to severe chemical conditions and temperature environments. Composites are often the material of choice for applications in chemical handling applications, corrosive environments, outdoor exposure, and other severe environments such as chemical processing plants, oil and gas refineries, pulp and paper converting, and water treatment facilities. Common applications include cabinets, ducts, fans, grating, hoods, pumps, and tanks [3, 37, 73]. Fibre-reinforced polymer composite pipes are used for everything from sewer upgrades and wastewater projects to desalination, oil, and gas applications. When corrosion becomes a problem with pipes made with traditional materials, fibre-reinforced polymer is a solution [3, 73].

5.7 Electrical

With the rapid growth of the electronics industry, and with strong dielectric properties including arc and track resistance, the composite materials are finding more and more in electronic applications. With strong dielectric properties including arc and track resistance, thermoset components include. Applications and components include arc chutes, arc shields, bus supports and lighting components, circuit breakers, control system components, metering devices, microwave antennas, motor controls, standoff insulators, standoffs and pole line hardware and printed wiring boards, substation equipment, switchgear, terminal blocks, and terminal boards [3, 75].

5.8 Energy

Material technology has grown from the early days of glass fibres as major reinforcements for composite material to carbon fibres which are lighter and stronger. The advancements in composites, particularly those from the US Department of Energy, are redefining the energy industry. Composites help enable the use of wind and solar power and improve the efficiency of traditional energy suppliers. Composite materials offer wind manufacturers strength and flexibility in processing with the added benefit of a lightweight components and products [3, 76]. The wind industry has set installation records over the last couple years. According to the Global Wind Energy Council, the trend for this industry may continue with global wind capacity predicted to double in the next few years. Composites play a vital role in the manufacture of structures such as wind turbine blades [3, 77].

5.9 Marine

Just like in the other engineering areas, the main struggle of naval architecture is to achieve a structure as light as possible. The marine industry uses composites to help make hulls lighter and more damage-resistant. With their corrosion resistance and light-weighting attributes, marine composite applications include boat hulls, bulkheads, deck, mast, propeller, and other components for military, commercial, and recreational boats and ships. Composites can be found in many more areas of a maritime vessel, including interior mouldings and furniture on super yachts [3, 78, 79].

5.10 Sports and recreation

The fibre-reinforced composite materials possess some excellent characteristics, including easy moulding, high elastic modulus, high strength, light in weight, good corrosion resistance, and so on. Therefore, fibre-reinforced composite materials have extensive applications in production the manufacturing of sports equipment. From bicycle frames, bobsleds fishing poles, football helmets, hockey sticks, horizontal bars, jumping board, kayaks, parallel bars, props, tennis rackets, to rowing, carbon fibres, and fibreglass composite materials help athletes reach their highest performance capabilities and provide durable and lightweight equipment [3, 80].

No comments:

Post a Comment